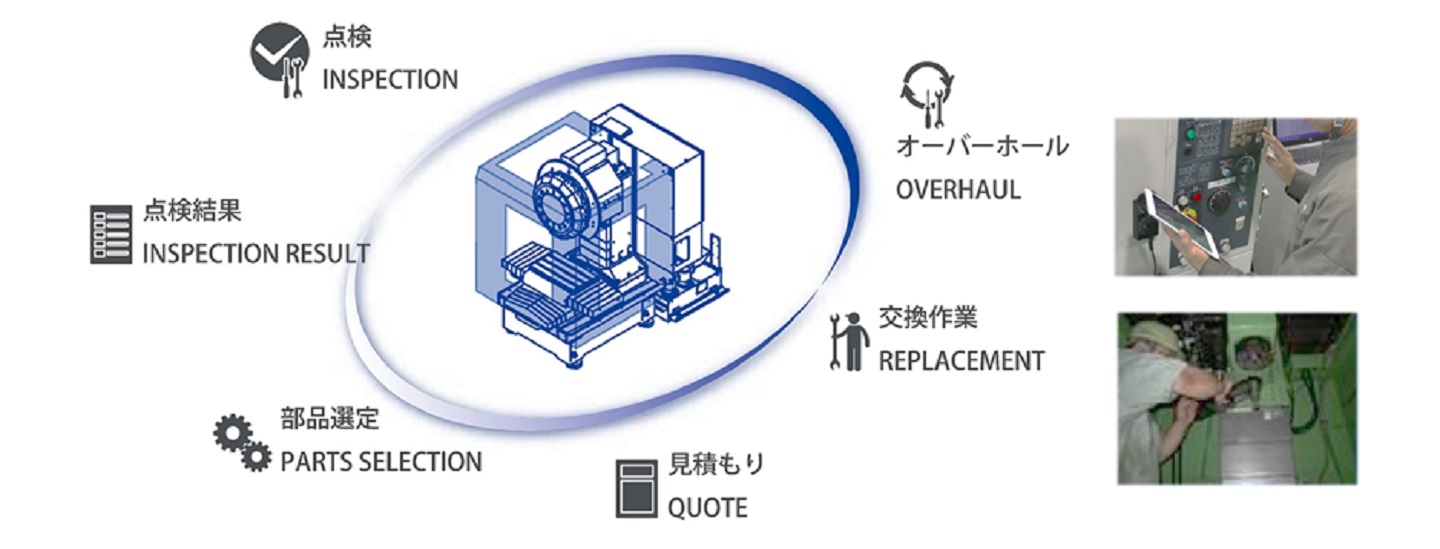

Preventative Maintenance Service

Our service team recommends preventative maintenance to ensure that our customers can continue to produce products with stable quality. Using specialized measuring instruments and check sheets for each model, we carefully inspect parts that are not normally visible to the naked eye. Based on the results, we select recommended replacement parts and make proposals for planned replacement not to disturb production. Through this initiative, we will reduce the number of sudden machine failures and stoppages. We also propose overhauls depending on machine usage.

- Inspection by staff visiting customer’s factory

- Inspection of normally invisible parts such as bearings of spindle and XYZ axis

- Inspection with measuring instruments to numerically determine the condition of components

- Planned maintenance by identifying the condition of parts before breakdown

- Selection and quotation of worn and deteriorated parts

- Suggestion of replacement parts and work details for overhaul

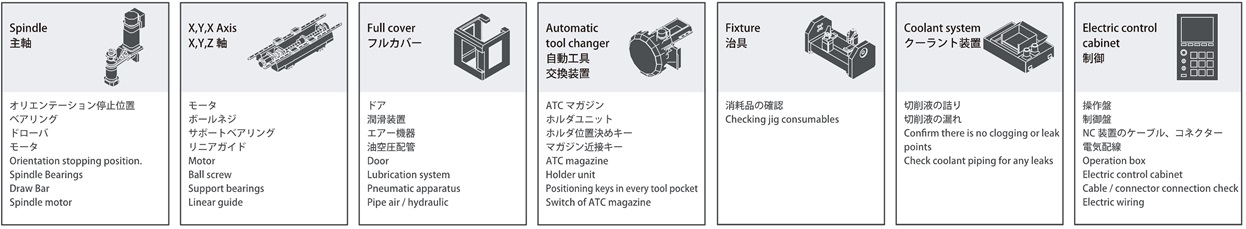

Main inspection points

Check sheet・Parts selection

Selection of recommended replacement parts with specialized check sheets for each model

Parts replacement・Overhaul

Proposal from recommended parts to overhaul plan