Ultrasonic spindle specialized for small-diameter hole and groove machining of brittle materials

Dramatically changes small-diameter machining of brittle materials (glass, silicon, ceramics, etc.)

Transmits ultrasonic vibration to the cutting edge, enabling machining of hard-to-cut materials

- Dramatic chipping reduction

- Tool life prolongation

- High aspect ratio hole drilling

Features

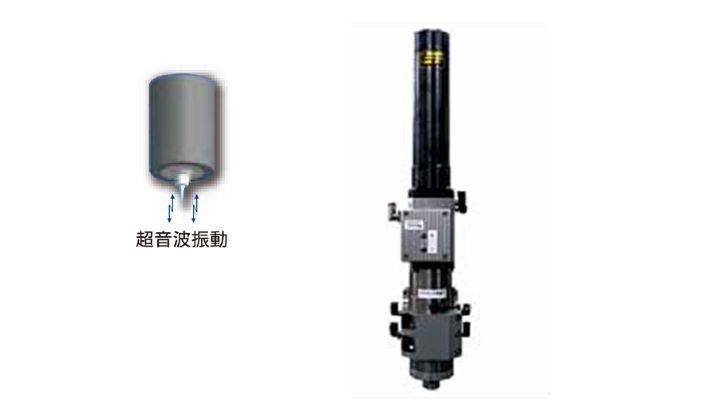

【Ultrasonic spindle】

Ultrasonic machine efficiently transmits ultrasonic vibrations generated by the ultrasonic transducer built inside to the tool tip. In the drilling and milling of brittle materials, micro fracturing is caused to reduce damage to the product and reduce clogging of the grinding stones.

【Merits of ultrasonic machining】

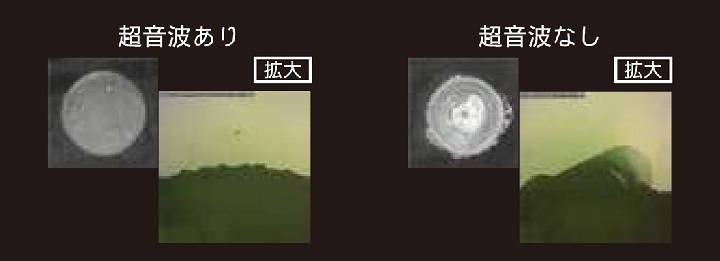

Chipping reduction

Damage-free processing by ultrasonic machining can reduce chipping.

Tool life prolongation

“Cavitation” by ultrasonic machining reduces clogging and prolongs tool life.

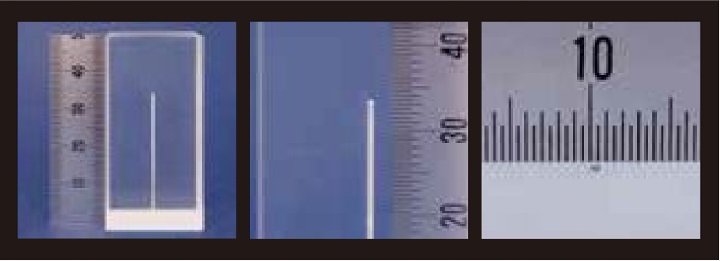

Machining of small-diameter deep holes

Ultrasonic vibration enables to machine small-diameter deep holes that are difficult to machine normally.

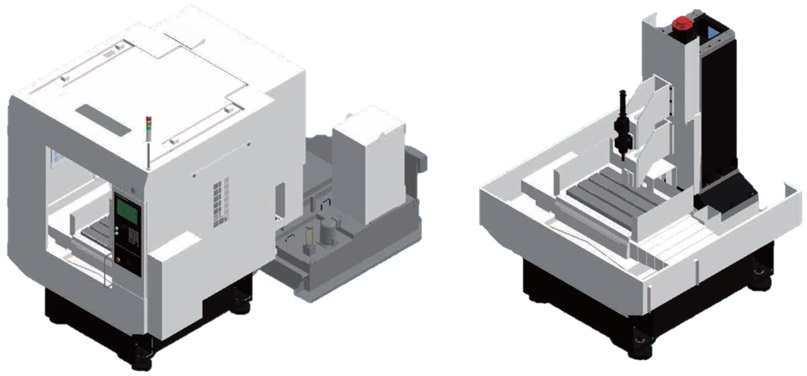

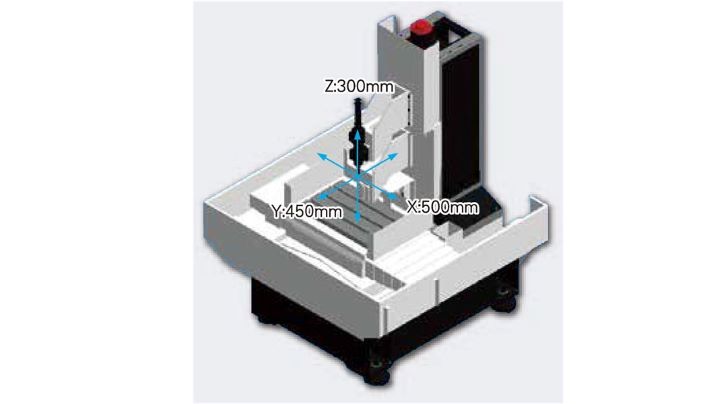

【Stroke and table】

XYZ axis stroke

500mm / 450mm / 300mm stroke

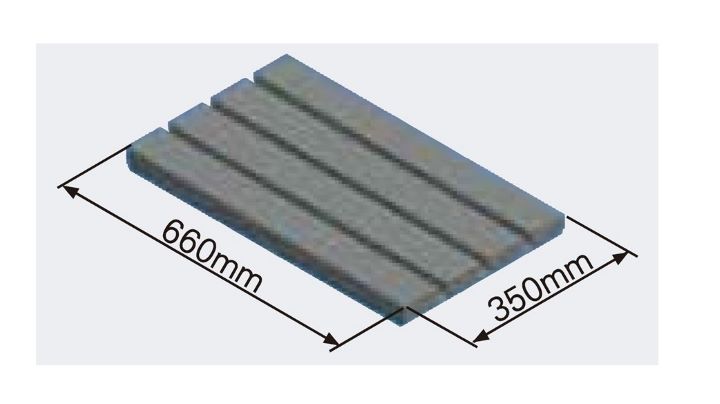

Table size 660mm x 350mm

Max. load capacity 150kg

【Specifications】 |

||

| Capacity | X-axis stroke | 500mm |

| Y-axis stroke |

450mm |

|

| Z-axis stroke | 300mm | |

| Table | Table size | 660mm x 350mm |

| Max. load capacity | 150kg (uniform load) | |

| Feed rate | Rapid traverse (X,Y,Z) | 30m/min |