Compact and high speed, condensed high performance will change the production line

Compact base machine for production line

Achieved high-efficient production line with variety of function for automation

- Uncompromising speeding up achieves high performance

- Compact base machine for production line

- Perfect base machine for automation

Features

【Productivity】

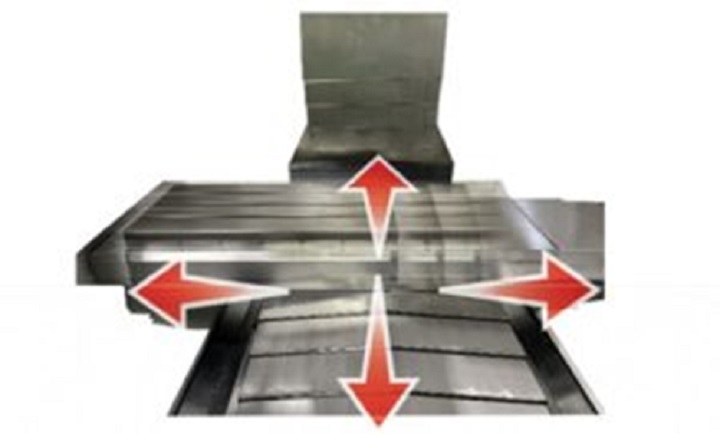

Increased speed of each axis

<Main specification> Rapid traverse 56m/min

Axis acceleration

0.86G(X),0.73G(Y),0.7G(Z)

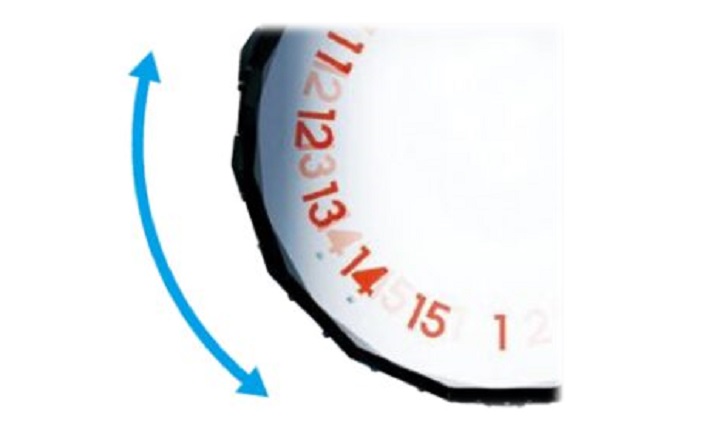

High-speed tool change system

<Main specification> T-T 1.8s / C-C 2.5s

【High performance】

Spindle

<Main specification>

Direct drive

Spindle speed

Standard 10000min-1 (15/11/7.5/5.5kW)

High speed 15000min-1 (7.5kW/5.5kW)

Ultra high speed 20000min-1 (9/5.5/3.7kW)

High rigidity 6000min-1 (18.5/15/11/7.5kW)

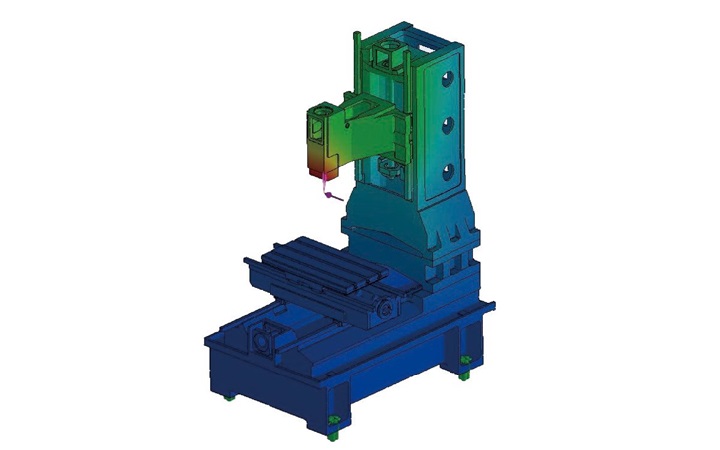

Rigidity

<Main specification>

Spindle diameter Φ70mm

Clamp force 8.8KN

Increased load rating of ball screws and linear guides

Table

<Main specification>

Table size 800mm x 400mm

Capacity 500kg

【Compact design, Suitable for production line】

Machine width 1800mm

This #40 machine has a compact design that makes efficient use of factory space.

【Specifications】 |

||

| Capacity | X-axis stroke | 700mm |

| Y-axis stroke |

standard:400mm |

|

Automation type:400mm (machining area) +200mm (loading area) |

||

| Z-axis stroke | 400mm | |

| Table | Table size | 800mm x 400mm |

| Max. load capacity | 500kg (uniform load) | |

| Spindle | Spindle speed | Standard type: 160-10000min-1 (15/11/7.5/5.5kW) |

HIgh speed type: 160-15000min-1 (7.5/5.5kW) |

||

Ultra high speed type: 160-20000min-1 (9/5.5/3.7kW) |

||

High rigidity type: 160-6000min-1 (18.5/15/11/7.5kW) |

||

| Taper | 7/24 taper No.40 | |

| Feed rate | Rapid traverse (X,Y,Z) | 56m/min |

| ATC | Tool shank | BT40 |

| No. of tools | 15 tools | |

| Machine dimension | Machine height | 2680mm |

| Floor space | 1800mm x 2768mm | |

| Mass of machine | Standard:Apporox. 3700kg | |