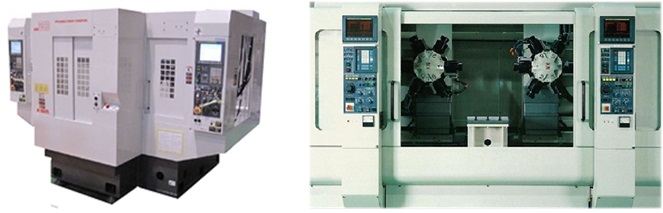

Ultra-high productive dual opposed machine revolutionizing the production line

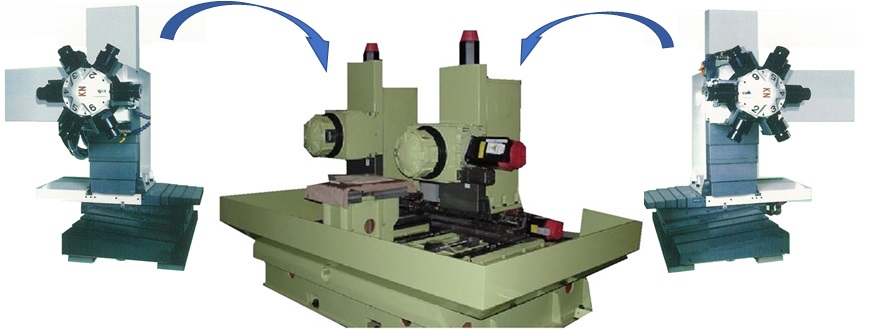

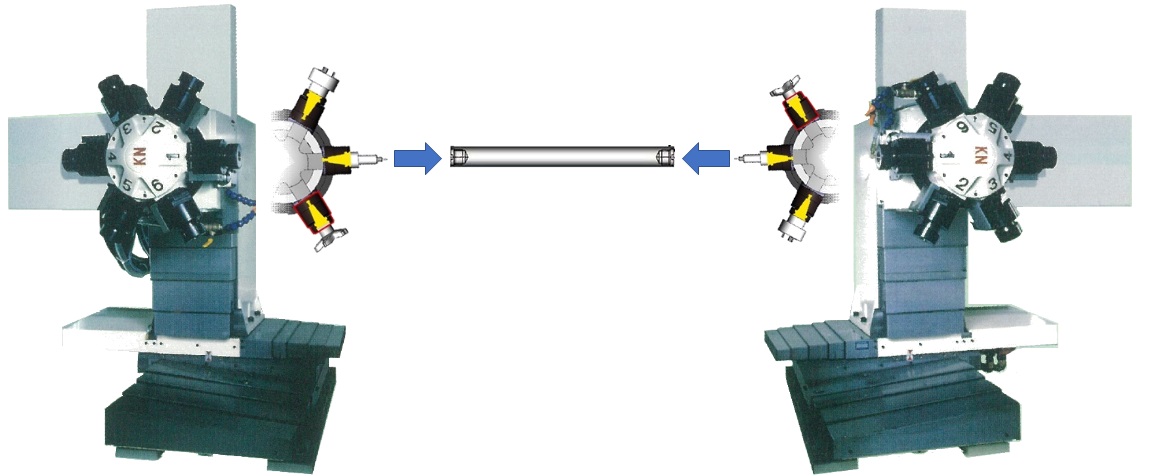

The 3-axis units are installed opposite each other to simultaneously machine both end faces of the workpiece.

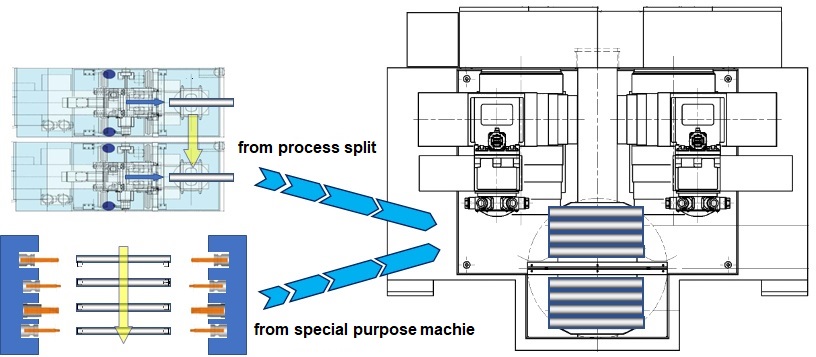

Process integration from dedicated machine to one machining center

- The 3-axis units are installed opposite each other within one machine to simultaneously machine both end faces of the workpiece

- Process integration from dedicated machine and separated machining to one machine

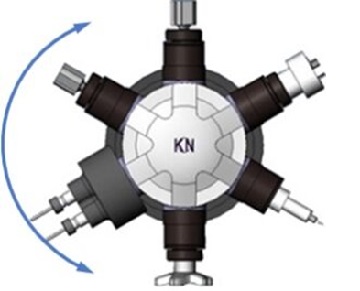

- Reduced cycle time by turret head of high-speed

Features

【Productivity】

The double 3-axis units are installed opposite each other within one machine.

The cycle time is greatly reduced by machining simultaneously both edge faces of the workpiece.

【Process integration】

Process integration from dedicated machine and separated machining to one machine.

【Other features】

High-speed ATC

The high-speed ATC with tool change time T-T 1.0s allows tool change at any location, greatly contributing to cycle time reduction.

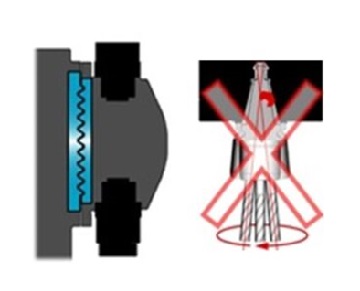

High accuracy turret head

The curvic coupling maintains high repeatability after ATC turning.

Pallet changer

Curvic coupling type pallet changer (2API) is available as an option for high productivity.

【Specifications】 |

||

| Capacity | X-axis stroke | 340mm |

| Y-axis stroke |

335mm |

|

| Z-axis stroke | 290mm | |

| Table | Table size | Standard:500mm x 300mm |

2API type:600mm x 350mm |

||

| Spindle | Spindle speed | Low:120-4000min-1 (3.7/2.2kW) |

Mid:240-8000min-1 (3.7/2.2kW) |

||

High:300-10000min-1 (3.7/2.2kW) |

||

| Feed rate | Rapid traverse (X,Y,Z) | 24m/min |

| ATC | Tool shank | — |

| No. of tools | 6 tools(standard) | |

8 tools(option) |

||