『Grinding Center』specializing in micro milling of brittle material parts

Various functions and options for high-precision machining

Special machine specifications for machining brittle materials, chip prevention, and anti-rust measures

- Specialized in micro milling of silicon, SiC, quartz glass, and various celamics

- Many features to improve the accuracy of machine specifications specialized for high precision machining

- Special specifications against fine chips of brittle materials and anti-rust for water-soluble coolant

Features

【High precision】

Linear scale

Linear scales with a resolution of 0.05μm are standard equipped on all axes.

Linear scales with a resolution of 0.05μm are standard equipped on all axes.

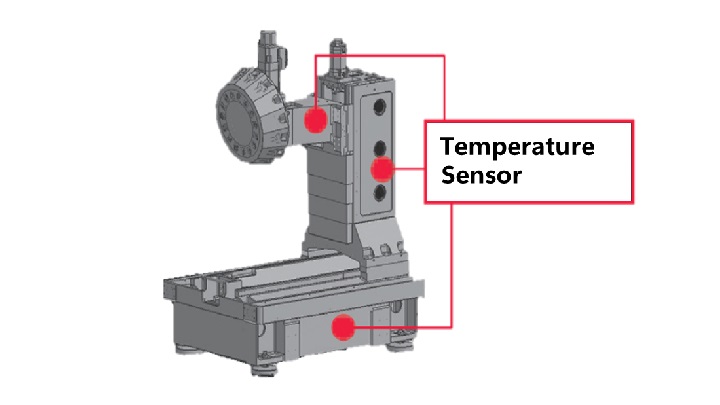

Thermal displacement compensation

Kira’s original thermal displacement compensation system is installed as standard equipment, and temperature changes are constantly monitored and compensated by multiple temperature sensors.

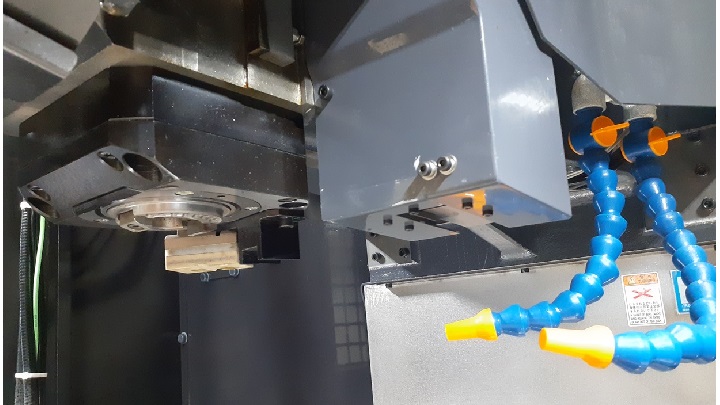

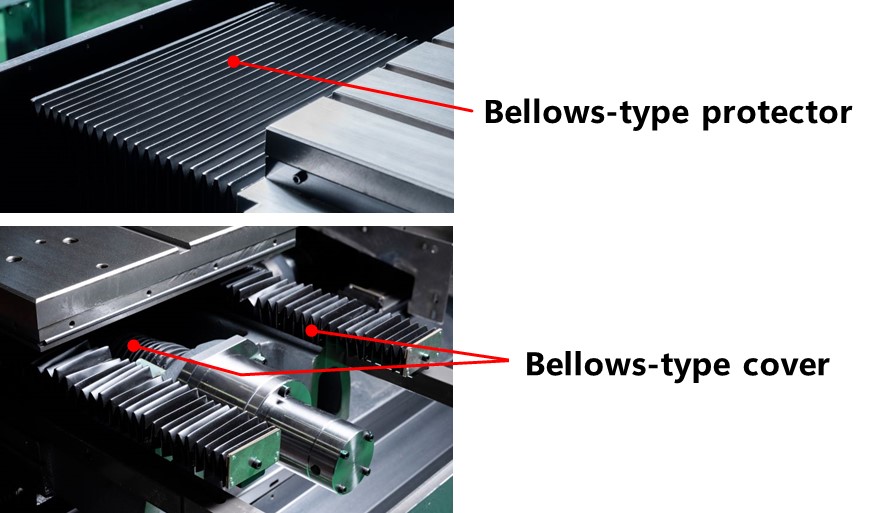

【Chip prevention and anti-rust measures】

Chip prevention

Bellows-type protectors against powdery chips of brittle materials are installed as standard. Ball screw and linear guide are also equipped with bellows type covers as standard.

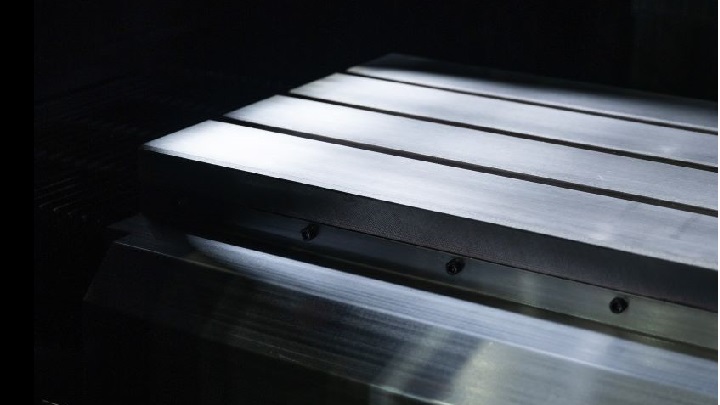

Anti-rust and stainless treatment

The top surface of table is protected by stainless steel to prevent rusting, even with water-soluble, low-concentration coolant.

Rust-Proof Fluoropolymer Coating

The ball screw and linear guide are coated with an industrial black chrome coating + special Fluoropolymer coating to cover the metal surfaces with a composite surface treatment, ensuring high rust-prevention capability.

【Specifications】 |

||

| Capacity | X-axis stroke | 700mm |

| Y-axis stroke |

400mm |

|

| Z-axis stroke | 400mm | |

| Table | Table size | 800mm x 400mm |

| Max. load capacity | 500kg (uniform load) | |

| Spindle | Spindle speed |

Standard: 15000min-1 |

High speed: 20000min-1 |

||

| Taper | 7/24 taper No.40 | |

| Feed rate | Rapid traverse (X,Y,Z) | 20m/min |

| ATC | Tool shank | BT40 |

| No. of tools | 24 tools (standard) | |

40 tools (option) |

||

| Machine dimension | Machine height | 3010mm |

| Floor space |

1900mm x 2220mm |

|

| Mass of machine | Apporox. 3800kg | |