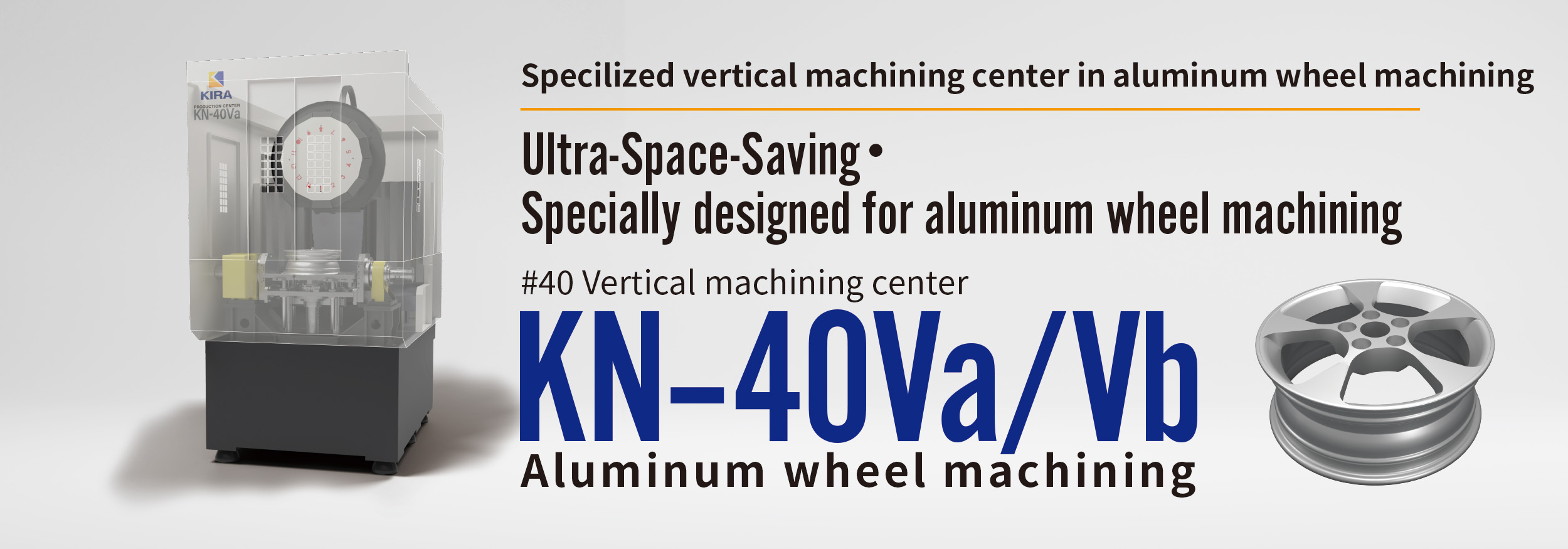

KN-40Va/Vb Aluminum Wheel Machining

KN-40Va/Vb Aluminum Wheel Machining

Specialized machine in aluminum wheel machining with saving space

Ultra-Space-Saving to effective use of floor space

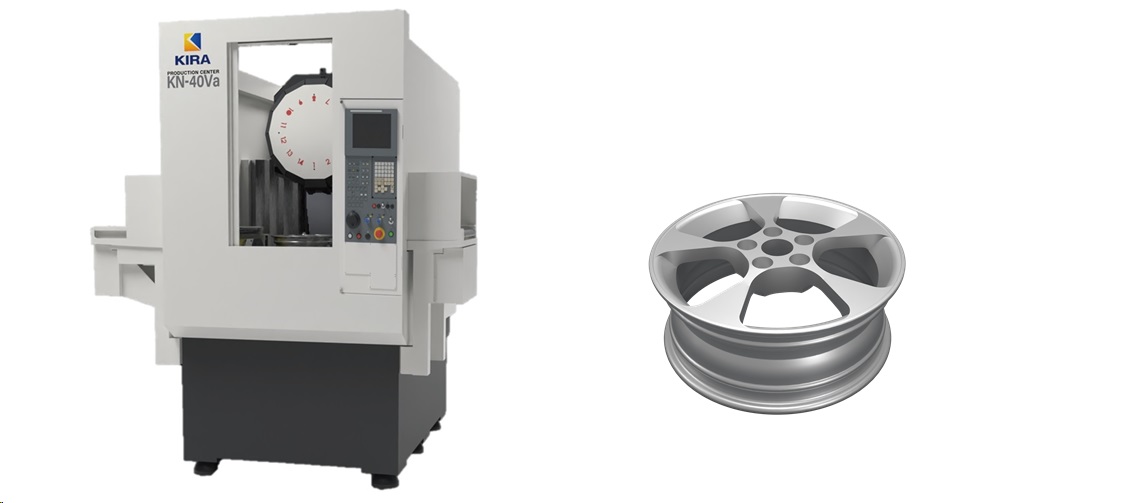

Machining bolt holes, valve holes and etc of aluminum wheel for automotive, which is performed on a small vertical machining center.The KN-40Va/Vb, which originally has a compact design, has been made even more space-saving for aluminum wheel machining, contributing to effective use of floor space.In addition, since it is a vertical machine and column moving type, the workpiece can be mounted horizontally, making it easy to loading and unloading the workpiece, and also enable smooth workpiece transfer between processes.This is an ultra-space-saving machining center that revolutionizes manufacturing sites.

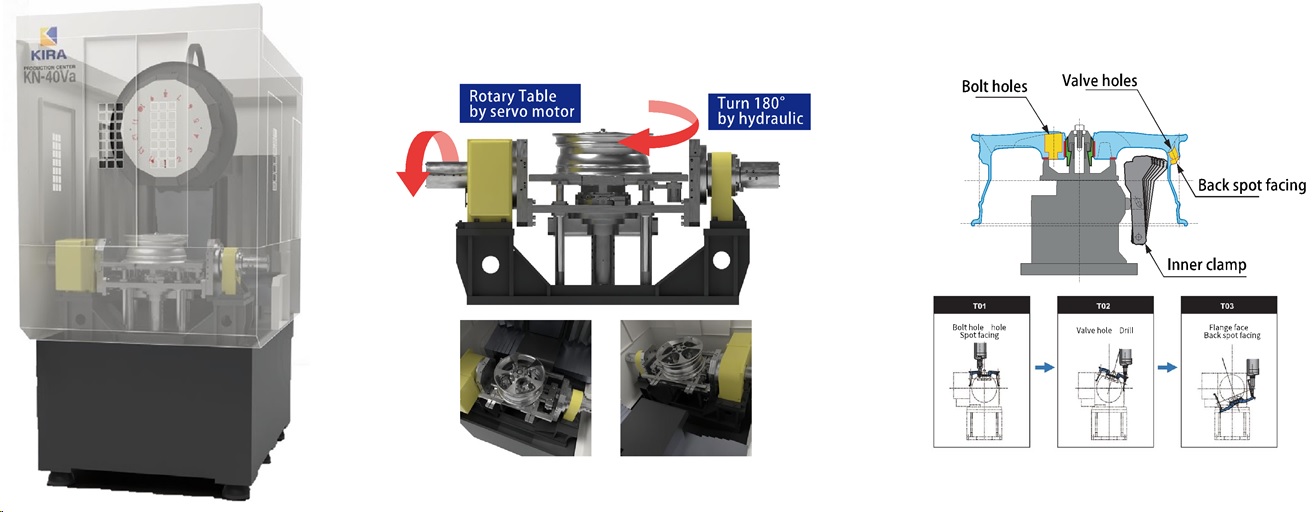

The jig is compact design that incorporates rotary table, and it is also possible to machine holes at various angles.

Dedicated design for aluminum wheel machining

Modify to center trough bed for improving chip flow

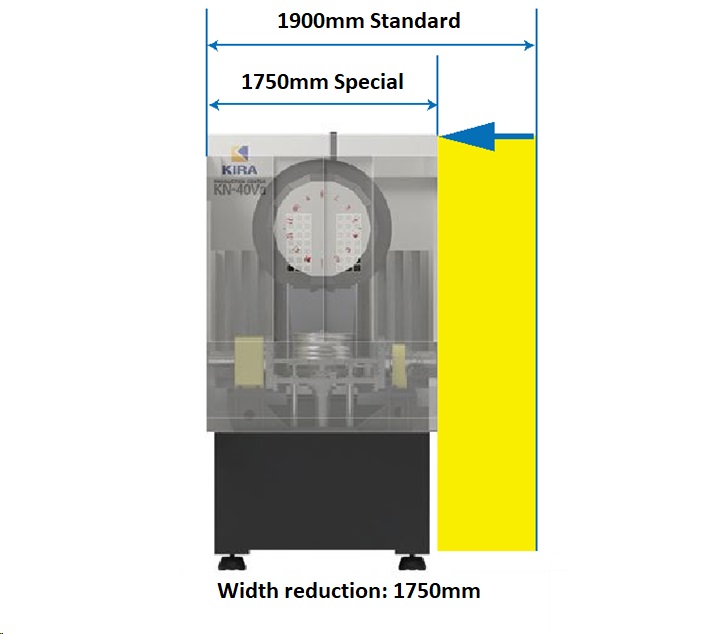

By using special bed for aluminum wheel machining, the extra X-axis stroke that is not necessary for drilling holes in aluminum wheels can be cut from 500mm to 200mm, reducing the machine width to 1750mm.

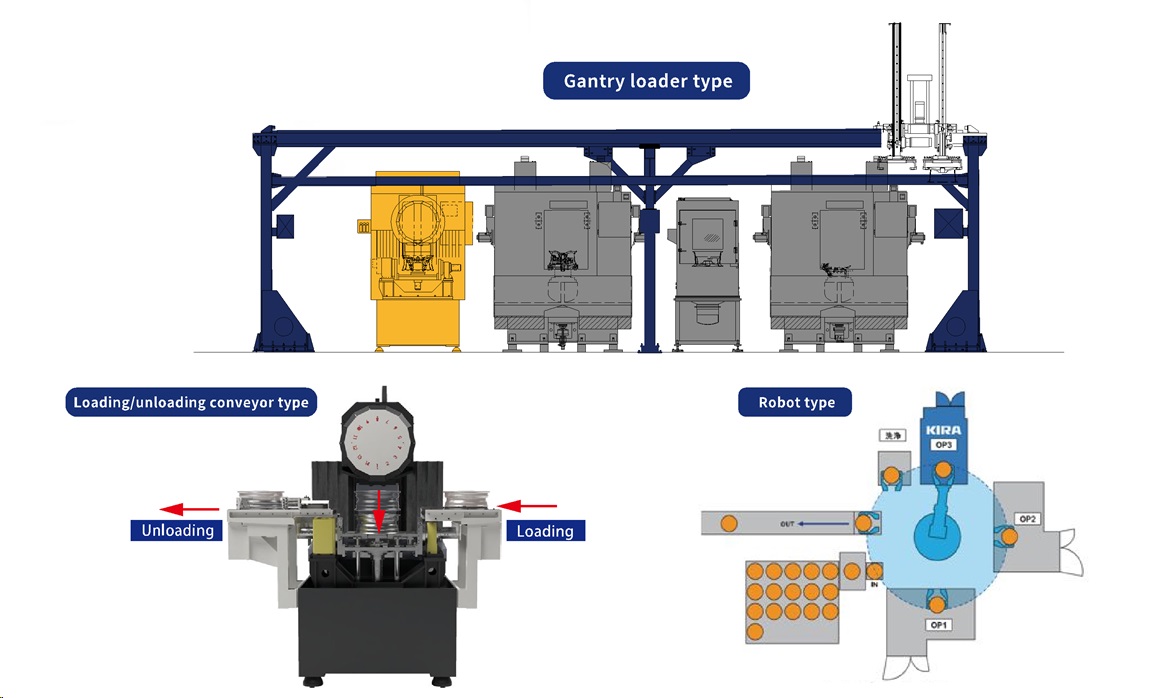

Further reduction of running costs in combination with automation

We flexibly support various automation tools such as gantry loaders, robots and conveyor loading/unloading. We can help you achieve an automated production line with higher operability.